1. Introduction –

In Australia's demanding industrial landscape—from petrochemical plants to power generation—materials face relentless stress from heat, pressure, and corrosive elements. Traditional stainless steels often fail when exposed to prolonged high temperatures, leading to premature failure, increased maintenance costs, and operational downtime. The solution? Choosing materials engineered for resilience—like Stainless Steel 321 Sheets.

2. Product Introduction –

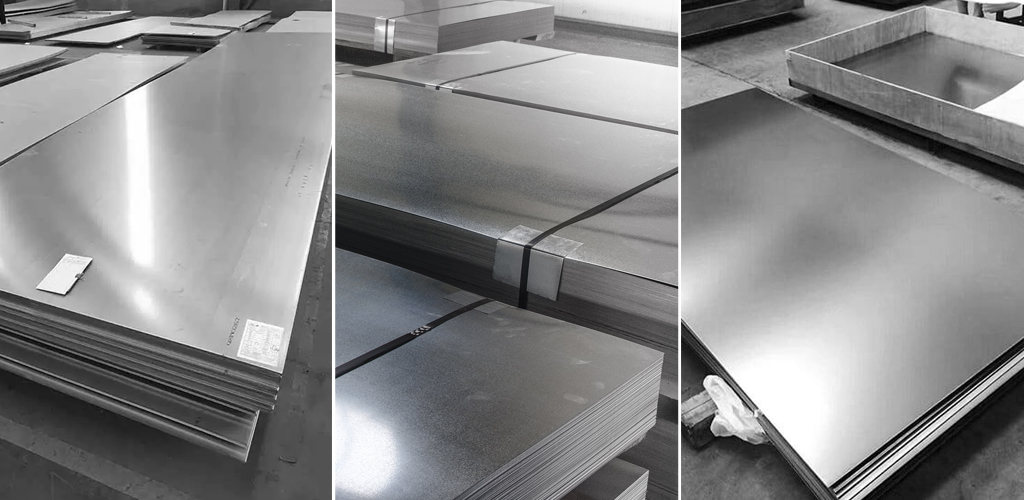

Stainless Steel 321 (SS 321) is a titanium-stabilized austenitic stainless steel designed specifically for high-temperature service. Classified under ASTM A240 and UNS S32100, it offers excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range (427–816°C). This makes SS 321 sheets ideal for applications involving sustained heating.

SS 321 Sheets are available in various thicknesses, finishes (2B, BA, No.4), and dimensions through trusted Stainless Steel 321 Sheets Suppliers and Stainless Steel 321 Sheets Stockists across Australia.

3. Advantages of Stainless Steel 321 Sheets

✅ High Temperature Resistance: Withstands temperatures up to 870°C, maintaining mechanical strength and corrosion resistance.

✅ Stabilized Against Intergranular Corrosion: The addition of titanium prevents carbide precipitation, making it superior to SS 304 in elevated heat environments.

✅ Excellent Weldability: Easily weldable without post-weld annealing.

✅ Good Formability and Fabrication: Easily fabricated into various structural and piping components.

✅ Longer Service Life: Reduced maintenance and replacement frequency due to enhanced durability.

4. Real Life Uses in Australia

???? Oil & Gas Pipelines in Western Australia – exposed to extreme heat and corrosive substances.

???? Heat Exchangers and Boiler Parts in power stations across New South Wales.

✈️ Aerospace Components where thermal stress is critical.

???? Chemical Processing Equipment in Victoria's industrial belt.

???? Automotive Exhaust Systems that require oxidation resistance.

These applications highlight why Stainless Steel 321 Sheets Stockists in Australia remain crucial partners for engineers and procurement specialists.

5. How SS 321 Sheets Solve Problems – and the Outcome

Before SS 321’s wide adoption, companies relying on SS 304 often experienced frequent failures due to carbide precipitation at high temperatures, leading to brittle welds and compromised equipment. With SS 321:

Companies have cut downtime by over 40% in high-heat applications.

Maintenance intervals have extended, reducing overall operating costs.

Welders and fabricators now prefer SS 321 due to its formability and resistance to post-weld issues.

The outcome? Safer, more efficient operations with fewer shutdowns—particularly in the demanding Australian industrial climate.

6. Conclusion – Smart Choice for Tough Conditions

Stainless Steel 321 Sheets have proven indispensable for industries requiring reliable performance under high thermal stress. With a growing network of Stainless Steel 321 Sheets Suppliers and Stockists in Australia, access to this robust material has never been easier.

Whether you're building for resilience or upgrading outdated infrastructure, SS 321 is your answer for long-term performance.